Account

Country

AUDI A8/S8/RS8

AUDI R8

AUDI Q3/SQ3

Audi Q8/SQ8

For automotive enthusiasts, few things are as exciting as upgrading their vehicles with high-performance parts, enhancing appearance and aerodynamics. Carbon fiber, renowned for its lightweight strength, has become a hallmark of high-end performance vehicles. However, when it comes to carbon fiber, not all types are created equal.

In this post, we dive deep into the two most common types of carbon fiber in the automotive industry: Pre-Preg (often called "dry carbon") and the more traditional wet carbon fiber. At Canadian Auto Performance, we've deliberately chosen to use Pre-Preg carbon fiber for many of our new parts, and we'll explain why this decision sets us apart.

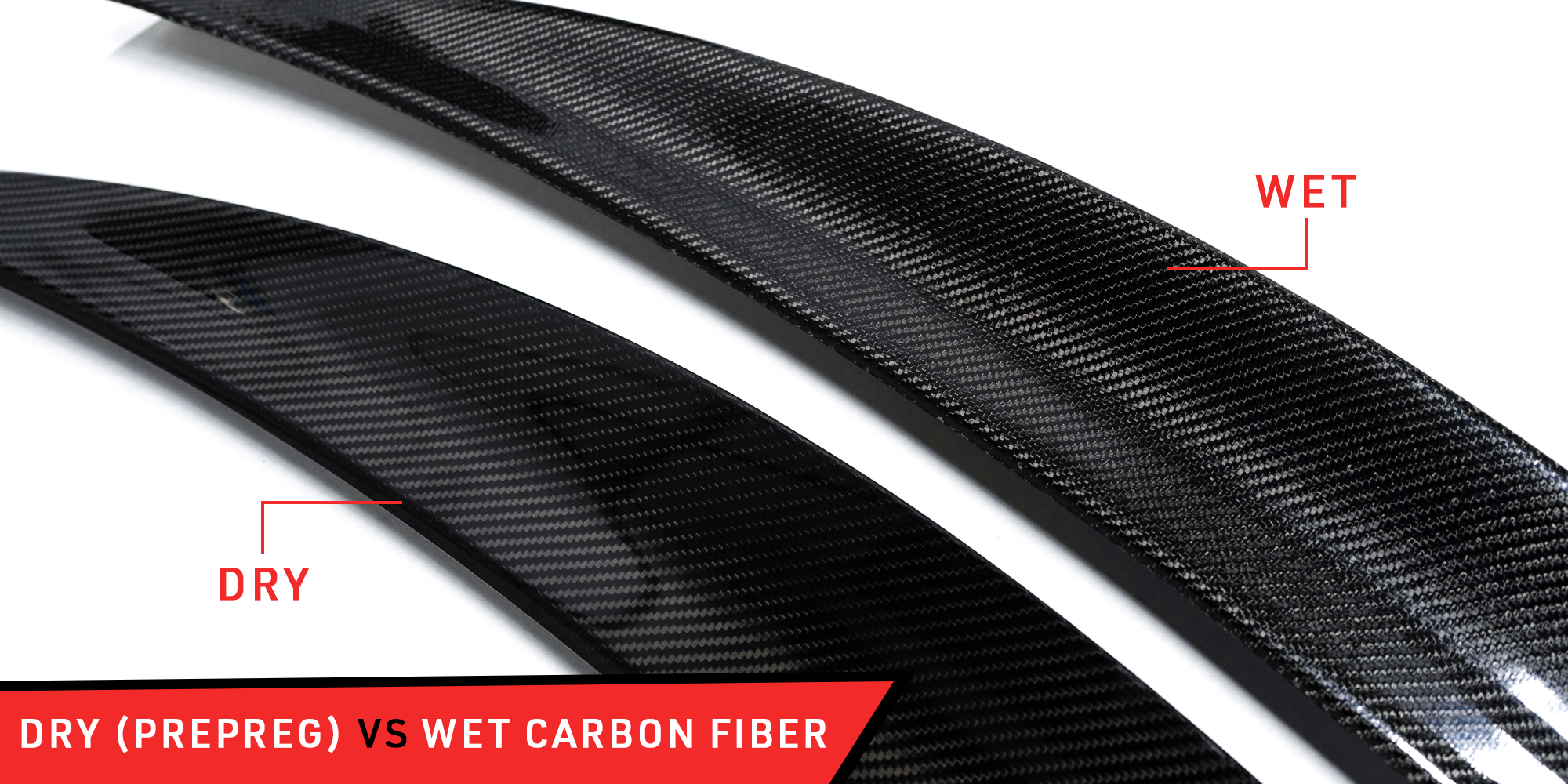

Pre-preg carbon fiber and wet carbon fiber are both composite materials using carbon fibers and resin, but they differ significantly in their manufacturing process and resulting properties.

Pre-preg carbon fiber is created by pre-impregnating the carbon fiber fabric with a precise amount of resin before curing. This ensures a uniform resin distribution and fiber-to-resin ratio throughout the material. The pre-impregnated sheets are then cured in an autoclave (a high-pressure, high-temperature oven) to create a strong, lightweight, and consistent material.

On the other hand, wet carbon fiber is produced by laying the carbon fiber fabric and then applying the resin by hand, either through brushing, spraying, or dipping. While more cost-effective, this method can lead to inconsistencies in resin distribution, potentially causing weak spots, excess weight, and an uneven finish.

Wet carbon fiber is a material created by hand-laying carbon fiber sheets and then soaking them in resin. This method is more manual and less controlled and can lead to inconsistencies in the final product. Wet carbon fiber material is often quicker and cheaper to produce, but this comes at the cost of durability and overall performance. While suitable for some applications, it falls short of Pre-Preg carbon fiber's benefits.

Pre-Preg carbon fiber is a composite material crafted with precision. It's made by pre-impregnating carbon fiber fabric with resin before the curing process. This means the fibers are already infused with resin and ready for molding. The material is then cured in an autoclave—a pressurized oven—where heat and pressure ensure a consistent, uniform bond between the resin and the fibers.

Pre-Preg carbon fiber is often called "dry carbon" because it doesn't require additional resin to be applied during the manufacturing process. However, "dry carbon" doesn't refer to a matte finish—it simply describes the manufacturing method. Pre-Preg carbon fiber can have a glossy finish, making it both strong and visually stunning on your car.

Dry carbon fiber is generally considered stronger than wet carbon fiber due to its manufacturing process. Dry carbon is pre-impregnated with resin before molding, resulting in a more uniform and precise carbon-to-resin ratio, leading to enhanced strength and lighter weight compared to wet carbon fiber.

At Canadian Auto Performance, we prioritize providing automotive enthusiasts with the highest quality parts that improve performance, aesthetics, and longevity. After extensive research and testing, we have strategically chosen to use Pre-Preg carbon fiber for most of our new products.

Here's why:

One of the most significant advantages of Pre-Preg carbon fiber is its superior strength-to-weight ratio.

Thanks to the pre-impregnation process, the resin is uniformly distributed, creating a stronger bond with the carbon fibers. This results in lighter yet stronger parts than their wet carbon fiber counterparts. The consistency of the manufacturing process eliminates weak points in the material, ensuring durability even under extreme conditions.

Wet carbon fiber, on the other hand, suffers from variations in resin distribution. This inconsistency can lead to weaker or more prone to damaged areas, compromising the structural integrity of the part.

Reducing weight is one of the primary reasons carbon fiber is so widely used in performance cars. This weight reduction improves acceleration, handling, and fuel efficiency, making Pre-Preg carbon fiber the ideal material for performance-driven parts.

Because Pre-Preg carbon fiber is carefully crafted with an optimal resin-to-fiber ratio, it is lighter than wet carbon fiber, which often contains excess resin that adds unnecessary weight. Pre-Preg is the best choice for those looking to shave pounds and enhance their vehicle's overall performance.

The high-precision process of creating Pre-Preg carbon fiber ensures a flawless finish. Each sheet is uniform, with a high-gloss finish and a premium clear coat that gives a polished, sleek look. For car owners who value aesthetics as much as performance, Pre-Preg is the clear choice.

Wet carbon fiber can sometimes suffer from air bubbles, resin drips, or uneven coloring, which detracts from the quality of the part and the overall look of your vehicle.

Parts are often exposed to extreme temperatures in high-performance applications. Pre-Preg carbon fiber is known for its excellent heat resistance, and the resin used in Pre-Preg parts is engineered to withstand higher temperatures without losing strength or structural integrity.

Wet carbon fiber is more prone to degradation under heat due to its less controlled resin application. This makes Pre-Preg carbon fiber a more reliable choice for parts exposed to high heat, such as engine covers, exhaust components, and brake ducts.

Although carbon fiber production is energy-intensive, Pre-Preg carbon fiber is more sustainable than wet carbon fiber. The process generates less waste, as it precisely applies resin to the carbon sheets, leaving no excess material to be discarded. Additionally, the durability and longer lifespan of Pre-Preg parts mean fewer replacements over time, contributing to a reduction in environmental impact.

While Pre-Preg carbon fiber offers significant advantages, it's essential to acknowledge a few potential limitations:

Higher initial cost: Pre-Preg parts can be more expensive upfront due to the advanced manufacturing processes.

Complex manufacturing: Pre-Preg manufacturing requires specialized equipment and expertise, which can contribute to the higher cost.

Limited repairability: Compared to wet carbon fiber, Pre-Preg parts can be more challenging to repair if damaged.

Reduced collision impact resistance: While Pre-Preg carbon fiber is exceptionally strong, it can be more susceptible to cracking under severe impact compared to some more flexible materials. This is a trade-off for the high strength and lightweight properties of Pre-Preg carbon fiber.

Despite these limitations, the performance benefits and long-term value of Pre-Preg carbon fiber often outweigh the drawbacks, especially for those seeking the highest quality and performance.

At Canadian Auto Performance, we leverage the advantages of Pre-Preg carbon fiber to create a range of high-performance parts. This includes exterior components such as spoilers, diffusers, and mirror caps, as well as performance-enhancing parts like exhaust systems. This allows us to offer our customers lightweight yet incredibly strong components that enhance their vehicles' aesthetics and performance.

The Pre-Preg carbon fiber manufacturing process involves several stages. First, carbon fiber sheets are pre-impregnated with resin, ensuring an even coating. These sheets are then laid into layers into molds, allowing for flexibility in creating custom shapes and designs. Once the parts are shaped, they are placed in an autoclave, where heat and pressure cure the resin, bonding it permanently to the carbon fibers. The result is a strong, lightweight, and durable part.

|

Feature |

Pre-Preg Carbon Fiber |

Wet Carbon Fiber |

|

Manufacturing Process |

Pre-impregnated resin, cured in autoclave |

Hand-laid resin, air-cured |

|

Strength |

High, consistent strength |

Inconsistent strength |

|

Weight |

Lightweight, optimal ratio |

Heavier, excess resin |

|

Finish |

Glossy, uniform, defect-free |

Potential defects, uneven finish |

|

Heat Resistance |

High resistance to heat |

Lower heat resistance |

|

Durability |

Long-lasting, superior performance |

Less durable, prone to damage |

Dry carbon fiber (Pre-Preg) requires minimal maintenance due to its durable, consistent resin application. Routine cleaning with a microfiber cloth and a non-abrasive cleaner will keep it looking pristine. Avoid harsh chemicals that could degrade the finish, and consider applying a UV protectant to guard against sun damage, especially for glossy finishes.

Wet carbon fiber, with its less controlled resin distribution, is more prone to surface imperfections like bubbles or uneven areas. Regular inspections are crucial to catch any signs of wear or damage early. If your wet carbon parts are exposed to high heat or moisture, they may require additional protective coatings to maintain durability and appearance over time.

As automotive technology advances and the demand for high-performance, lightweight parts grows, Pre-Preg carbon fiber is positioned to become the go-to material for car enthusiasts, racers, and manufacturers. Canadian Auto Performance is proud to be a leader in offering Pre-Preg carbon fiber products that deliver unparalleled performance, aesthetic appeal, and longevity.

While the initial material cost of pre-preg is higher than that of wet carbon fiber, the manufacturing process can offer cost benefits in the long run. Pre-preg's precise nature and consistent quality often lead to reduced finishing time and lower scrap rates. Additionally, the longer lifespan of Pre-Preg parts translates to less frequent replacements, contributing to cost savings over time.

By choosing Pre-Preg carbon fiber, we provide our customers with the most advanced, durable, and high-performance parts available. Whether driving an Audi, BMW, Tesla, or another high-performance vehicle, upgrading to Pre-Preg carbon fiber will elevate your car's capabilities and appearance.

At Canadian Auto Performance, we're dedicated to providing the best automotive performance parts, and that means using the best materials available. Pre-Preg carbon fiber is the superior choice for high performance, quality, and a sleek appearance. Whether you're upgrading your Audi, BMW, or Tesla, our Pre-Preg carbon fiber parts will help you achieve the performance and look you desire.

Ready to take your vehicle to the next level? Explore our range of Pre-Preg carbon fiber parts and experience the difference today!

Pre-Preg carbon fiber is generally more expensive due to several factors:

Higher-quality materials: Pre-Preg often uses higher-grade carbon fiber and resin systems.

Advanced manufacturing: The pre-impregnation process and autoclave curing require specialized equipment and expertise, adding to the cost.

Increased labor: The precise nature of Pre-Preg manufacturing often involves more skilled labor and time.

Lower production volume: Pre-Preg is often produced in smaller quantities than wet carbon fiber, contributing to higher costs.

While the initial cost of Pre-Preg carbon fiber is higher, its superior performance, durability, and lighter weight can offer long-term value and benefits.

Pre-Preg carbon fiber offers several performance advantages:

Reduced weight: Pre-Preg parts are significantly lighter than their wet carbon fiber counterparts, improving acceleration, braking, and fuel efficiency.

Enhanced strength: The consistent resin distribution in Pre-Preg results in greater strength and stiffness, improving handling and overall vehicle dynamics.

Increased heat resistance: Pre-Preg carbon fiber can withstand higher temperatures, making it ideal for parts exposed to engine heat or braking systems.

These factors contribute to a noticeable improvement in vehicle performance, making Pre-Preg carbon fiber a popular choice for performance enthusiasts and racing applications.

Visually, Pre-Preg carbon fiber typically has a more consistent and flawless appearance. The weave pattern is uniform, and the finish is generally smoother, with a high gloss. Wet carbon fiber, due to its manual layup process, may have inconsistencies such as:

Air bubbles: Trapped air during resin application can create visible bubbles in the finished product.

Uneven resin distribution: This can lead to a wavy or uneven surface, with some areas appearing thicker or thinner than others.

Non-uniform weave: The weave pattern may appear distorted or uneven due to inconsistencies in the hand layup process.

While the production of carbon fiber is energy-intensive, Pre-Preg carbon fiber offers some environmental advantages over wet layup:

Reduced waste: The precise resin application in Pre-Preg minimizes excess resin and material waste during manufacturing.

Longer lifespan: Pre-Preg parts are more durable and less prone to damage, reducing the need for replacements and minimizing waste over time.

In short, even the highest-grade wet carbon cannot compete with high-grade dry carbon in terms of weight, durability, or aesthetics, making dry carbon the gold standard for high-performance applications. While both use high-quality materials, wet carbon inherently has more resin pooling and inconsistencies, resulting in a heavier and less refined finish compared to dry carbon.

Keeping your carbon fiber parts looking their best is simple:

Use a soft microfiber cloth and a pH-neutral cleaner for cleaning.

Apply a UV protectant (such as Ceramic coatings or PPF) to guard against sun damage.

Avoid harsh chemicals or abrasive tools that could damage the finish.

Regularly inspect for signs of wear, especially on high-impact areas.

At CAP, we provide detailed care tips for each product, ensuring your investment stays in top condition for years to come.

While Canadian Auto Performance initially focused on European models like Audi, BMW, and Tesla, we are actively expanding our product line to include Pre-Preg carbon fiber parts for a wider range of vehicles. This includes Tesla and other popular models, ensuring that more car enthusiasts can experience the benefits of this advanced material.